Hybond Insight: A behind-the-scenes look inside our adhesives testing lab

Hybond’s ability to carry out adhesive bond testing in-house, create bespoke adhesive formulations, and replicate factory processes in a controlled environment offers a unique advantage to our customers – and is all available from our dedicated facilities.

Recently members of Hybond’s marketing team got an invitation to visit the Hybond adhesive testing lab right here on-site alongside our offices and warehouse facility in central Shropshire. They spent the day with our Technical Director and members of the laboratory team, getting a unique insight into some exciting projects currently underway. Let’s take a look at some of the highlights of their visit:

FIRST UP: A BESPOKE FORMULATION IS TAKING SHAPE!

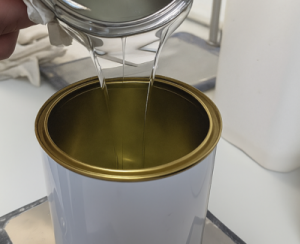

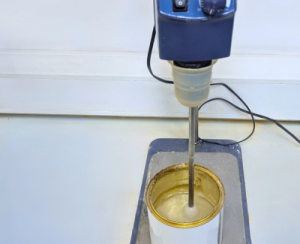

Our lab team thrives on a challenge, and creating bespoke adhesive formulations is right up their alley. One recent project involved a modified UV-cured hot melt acrylic adhesive for a graphics industry customer. You can further explore our adhesive range here.

The previous version worked well but was a little too viscous for the customer’s requirements, so the team experimented with lower-viscosity raw materials to hit the perfect balance. Watching the mixing process—adding precise amounts of dry and liquid ingredients—offered a fascinating glimpse into the care and precision behind every custom formula.

Our in-house expertise lets customers tweak, test, and perfect their adhesive choice in a controlled environment before production.

NEXT STEP: GETTING THE COAT WEIGHT JUST RIGHT!

Once the bespoke adhesive was mixed, the next step was replicating its application as it would happen in a factory. Using a Pull Down Meyer Bar – a smooth rod wrapped with fine wire that creates tiny grooves along its length – the team could apply the adhesive at a precise, controlled coat weight. Different bar sizes produce varying coat weights, letting us closely mimic customer processes in a lab setting. This glue application equipment ensures consistency and lets the lab fine-tune the formula before it reaches full-scale production.

TIME FOR: UV CURING UNDER THE SPOTLIGHT

UV light transitions the adhesive from liquid to tacky.

With the adhesive applied at the correct coat weight, the lab team tested its curing under UV light. This step verifies that the formulation responds perfectly to the curing process, ensuring performance and reliability.

Take a look at the glowing adhesive under UV light, it gives a real sense of the science in action – and shows how closely we monitor every detail to get the perfect result.

WHAT ELSE: A FEW MORE LAB OBSERVATIONS FROM THE DAY

LEFT: Plasma treatment prepares plastic for bonding.

We watched as a strip of low surface energy plastic, destined for use in the marine industry, underwent plasma treatment. This process cleans and activates the surface, making it far easier for adhesives to bond effectively. Plastics are notoriously difficult to bond due to their low surface energy, but plasma treatment provides an effective way to achieve a strong, reliable bond.

CENTER: Dyne testing confirms improved surface energy.

Once treated, the same plastic underwent Dyne testing. A purple Dyne liquid was drawn across the surface, and whether it beads or holds a line allows our team to establish a Dyne reading. The Dyne kit contains liquids of varying surface tension, applied one by one until a solid, unbroken line is achieved. This confirms the plasma treatment has successfully raised the material’s surface energy.

Click here for our dedicated plastic treatments blog post!

RIGHT: A one-of-a-kind heated pneumatic press.

The final highlight was Hybond’s bespoke heated pneumatic prototyping press. Unique to our lab, this kit replicates large-scale factory pressing on a smaller scale, making it a versatile tool for projects ranging from kitchen panels to automotive parts.

IT’S A WRAP!

That wraps up our latest lab tour. From bespoke formulations and plasma sparks to purple Dyne lines and our one-of-a-kind prototyping press, it’s clear the Hybond lab is full of innovation and practical problem-solving. It’s all part of how we help customers take their bonding challenges from concept to reality.

Could your manufacturing operation benefit from the expertise and services of the Hybond technical team?

CONTACT US TODAY