Hybond Insight: Navigating bonding challenges within PIR production

PIR insulation boards are a leading choice of insulation material in the modern construction sector, thanks particularly to their thermal efficiency and lightweight nature. When it comes to manufacturing these composite panels – whether for roofing, walls, or other specialist applications – the adhesive bonding process plays a critical role in achieving consistent results.

As leading adhesive specialists operating within the construction industry, Hybond’s technical team have been examining a range of PIR samples to better understand the unique bonding challenges that manufacturers face, and how best to overcome them.

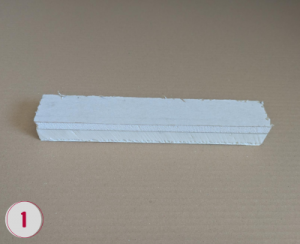

COMMON PIR COMPOSITE CONSTRUCTIONS

Take a look at some popular configurations – each type requires a specific adhesive strategy to ensure a strong, stable bond.

- PIR bonded to plasterboard, typically faced with a paper-based foil. These are widely used for internal wall insulation.

- PIR sandwich panels, faced with aluminium foil. These high-performance panels offer increased rigidity and insulation performance.

- Roofing-grade PIR boards with a coarse, black mineral or bitumen-impregnated facer.

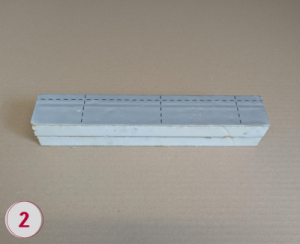

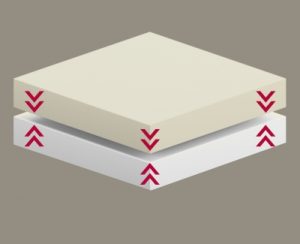

WHY DOUBLE-LAYER PIR SANDWICHES?

Working closely with a variety of PIR producers, our technical team have noted that many manufacturers opt for the sandwiching of two layers of PIR, rather than using a thicker single layer. This can be seen in pictures 2 and 3 above. While the exact reasons vary, a sandwiched design can provide mechanical stability, production flexibility and reduce cost as follows:

Improved dimensional stability

Two bonded layers can offer better resistance to bowing or warping.

Production flexibility

Sandwich layers allow manufacturers to use standard board formats and combine them into a wider range of products.

Cost-effectiveness

It may be more economical to use two thinner cores depending on raw material supply or plant equipment limitations.

WHEN BONDING FAILS – IT’S NOT ALWAYS THE ADHESIVE!

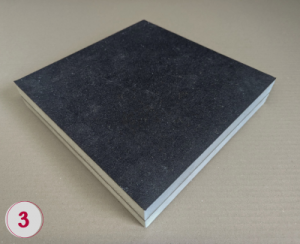

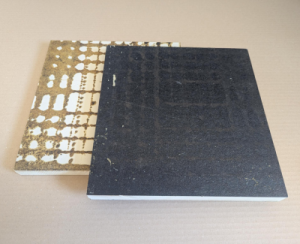

Let’s take a closer look at Sample 3 — the roofing-grade PIR board faced with a coarse, black mineral or bitumen-based layer. These facings are designed to provide durability and weather resistance, but they pose a unique challenge for adhesive bonding. Rather than the adhesive failing, we often see the top layer of the facer itself breaking away, making it difficult to achieve a reliable bond.

Delamination shown: Black facer tears from PIR core.

In the image shown here, you can observe this issue first-hand. During a tensile test conducted by our technical team, two of these boards were bonded together in a sandwich configuration. When force was applied, the adhesive held — but the coarse mineral surface of the right-hand board partially detached and remained on the left-hand board.

This left clear residue patterns on the white PIR substrate, showing where the mineral facing delaminated under stress.

This is a textbook case of adhesive application and surface compatibility being the root of failure — not the adhesive itself. In scenarios like this, it’s not just about what glue you choose, but how it interacts with the surface it’s applied to.

SURFACE PREPARATION – THE KEY TO RELIABLE BONDING

PIR facings vary in texture, porosity, and chemical composition. Some are easy to bond to; others require more finesse.

At Hybond, we address this by:

✓ Assessing the substrate surface

✓ Selecting intelligent primer systems

✓ Running in-house trials to simulate real-world conditions

Primers stabilise porous or dusty surfaces, boosting wetting and bond strength. On coarse facers, they prevent surface flaking. Whether bonding facers, or laminating PIR layers, Hybond help optimise adhesive performance and production outcomes.

In recent adhesive trials, through careful process evaluation and optimisation; Hybond successfully improved the tensile bond strength of customer provided sample PIR boards from a low reading of 17 kPa to 150 kPa — as confirmed by tensometer testing. A tensile strength of 150 kPa means the bond can now withstand a pulling force of 150,000 pascals per square metre before failing.

OUR PREFERRED ADHESIVE SOLUTION

At Hybond, our go-to adhesive for PIR panel production is a trusted one-part liquid polyurethane (PU). This versatile formulation is suitable for all the PIR types detailed above — from foil-faced to coarse mineral-coated facers.

Hybond’s PU formula keeps panels aligned when bonded.

Why we recommend it:

✓ High bond strength across multiple facer types

✓ Low calorific value — ideal for fire-rated (FR) panel applications

✓ Low isocyanate content — supporting safer handling and improved compliance

Take a look at the adhesive in action to the left — here it’s applied via a bead laminator to a paper-faced PIR board. Unlike some PU adhesives that allow bonded PIR boards to shift after application due to their thixotropic nature, our preferred grade grips immediately, helping to prevent misalignment during sandwiching.

READY TO OVERCOME YOUR PIR BOARD BONDING CHALLENGES?

CONTACT Hybond today

Our technical team is on hand to help you select the right adhesive, improve your process, and achieve reliable results.